The 3D packing methods in Fusion

When it comes to the part packing process, also known as 3D nesting, the choice of variations of different nesting methods can significantly impact efficiency and results, as each variation has its own distinct methodologies and performance characteristics.

Autodesk Fusion offers three different 3D nesting methods: Bounding Box, Monte Carlo, and True Shape. The reason the application provides three different options is that each method has its own relative merits, and users may find that certain methods are more advantageous in certain applications.

So, what are the advantages and limitations of each method?

)

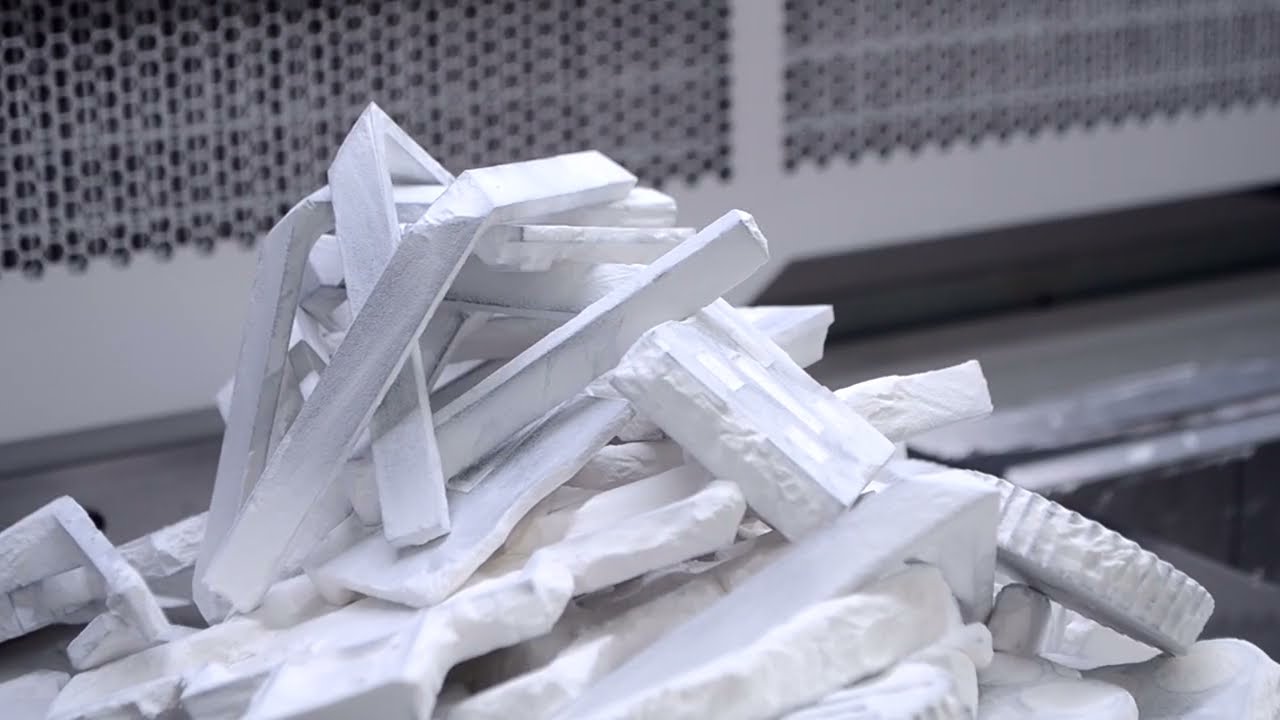

Bounding Box packing

Nesting by bounding boxes is the simplest of these three methods and is the best choice for those new to nesting parts. This method uses the bounding box of the object to calculate how to optimally nest the parts into a 3D volume. The main advantage of nesting with the Bounding Box method is its simplicity and ease of use.

However, the very simplicity of Bounding Box nesting has limitations. It does not offer any possibility of rotating the parts, which can lead to inefficient use of space. In addition, it cannot duplicate parts during the packing process. Thus, parts must be duplicated manually before packing. Despite these drawbacks, however, Bounding Box nesting ensures that parts do not overlap and can pack parts around non-printable zones as well as pre-positioned parts. Bounding Box packing will therefore be most suitable for simple block-like parts.

Key features:

Dependence on the bounding block can lead to lower packing density

Ensures that parts do not overlap each other (interlock)

Can handle non-printable, no-build zones and locked parts

Does not rotate parts during packing

Does not duplicate parts during packing

Monte Carlo packing

Monte Carlo packing is more advanced than the Bounding Box method. It is a translation-based nesting algorithm that uses a random initial arrangement of parts before moving them down into the available space during the packing process. Arranging the parts using a Monte Carlo packer prevents them from interlocking by avoiding overlapping each other when moving them. However, due to the random initial arrangement of the parts, the results are not repeatable, which can be a disadvantage in scenarios requiring consistency.

Unlike the Bounding Box method, the Monte Carlo packer includes a preprocessing step that allows the parts to be rotated before packing. This preprocessing step increases the efficiency of space utilisation. It can also handle non-printable zones. Overall, its ability to rotate parts before packing and its voxel-based nesting algorithm make it a better choice compared to the Bounding Box packer for those users looking for greater efficiency, especially for more complex parts.

Key features:

Voxel approach

Nester based translation/shift with random initial ordering

Ensures that parts do not overlap each other

Can accommodate non-printable zones and locked parts

Ability to rotate parts before packing

Does not rotate parts during packing

Dependence on feed path may result in lower packing density

Does not generate repeatable results due to random initial placement of parts

Does not duplicate parts during packing

True Shape packing

True Shape is a new packing method that is a successor to the Monte Carlo method and provides users with another high-performance variant of 3D nesting. It also uses a voxel-based approach, checking the voxel representation of the available print volume before placing parts. This method also offers full rotational control during packing. This means that for any given part, you can control what rotation can be accounted for before placing the part in the build volume. The rotation control options available with this packer greatly increase space utilisation and efficiency.

One of the main advantages of True Shape packing is the ability to create duplicates during the packing process. This approach is much faster and more efficient than manually creating duplicates prior to packing. True Shape packing eliminates the need to reprocess each duplicate after voxelizing the part, saving time and computing resources. This makes True Shape packer the fastest method for nesting multiple copies of a part.

Key features:

Voxel-based approach

Ensures that parts do not overlap each other

Can accommodate non-printable zones and locked parts

Ability to rotate parts during packing

Ability to duplicate parts during packing

Generates repeatable results

Conclusion

In conclusion, all three arrangement methods allow users to prioritise the nesting of parts according to their volume or order of selection, offering flexibility in nesting strategies. The Bounding Box nesting algorithm is a great choice for beginners due to its simplicity and ease of use, but it lacks efficiency and flexibility.

The Monte Carlo and True Shape nesting algorithms both offer significant improvements by enabling part rotation before and during the nesting process, respectively, and use voxel-based nesting algorithms. However, when comparing overall nesting performance, True Shape packing is the clear winner.

While the Monte Carlo method is a great choice, True Shape packer stands out as the better algorithm. It provides full rotation control, adapts seamlessly to complex geometries, supports duplication of parts during packing, and ensures repeatable results. For users with a commercial Fusion license, True Shape Packing is undoubtedly the best choice for efficient and reliable 3D nesting.

More information

You can download the localised CAD/CAM application Autodesk Fusion and try it out. More about Autodesk Fusion.

(Based on material originally shared in the Fusion blog)

)